charpy impact test shiny area|charpy impact testing procedure : Brand manufacturer Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Resultado da 26 de out. de 2022 · Na Avenida Rebouças, em Pinheiros, o chef francês Erick Jacquin agora comanda o Steak Bife, sua quinta casa na capital .

{plog:ftitle_list}

Celebrating 30 years of tradition, Wheel of Fortune® Triple Extreme Spin brings all the excitement and thrills of “America’s Game” to this bonus-filled bonanza. This online slots experience features an incredible collection of MultiWay Xtra gameplay features with big win potential, including the Mini Wheel Bonus and Triple Extreme Bonus.

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

The Charpy impact specimens of each material are immersed in a bath for 10 minutes to reach thermal equilibrium at five separate temperatures ranging from -110oF (-79oC) to 212oF . In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area.

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a .

In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area. At present, the measurements of absorbed energy and lateral expansion are quantitative and well defined, but the methods used by most laboratories in the measurement of percent shear are qualitative at best. Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. . value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch . Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015). Ensayo de Impacto Charpy con Muesca en V: En este ensayo, se utiliza un espécimen en forma de una probeta en forma de V con una muesca en el centro. La probeta se coloca en una máquina de ensayo de impacto y se golpea con un martillo pendular que tiene una energía cinética conocida. La cantidad de energía absorbida por el material antes de .

The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

charpy impact testing procedure

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . Brittle fracture looks clear, shiny with surfaces while ductile fracture looks greyish and fibrous.The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .The Charpy impact test, also known as the Charpy v-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.This absorbed energy is a measure of a given material's toughness and acts as a tool to study temperature-dependent brittle-ductile transition.

boucheron jaipur batch code etched on tester bottle

Explore Charpy Impact Testing, a reliable method for assessing material toughness. Learn how it works, key benefits, and how to interpret Charpy impact test results for industrial use. . A brittle fracture will appear smooth and shiny, while a ductile fracture will show a rougher, fibrous surface. 3. Temperature Effects Several researchers have focused their work, both experimental and numerical, in the area of impact testing to analyse different materials behavior. Banerjee et al. . Determination of Johnson cook material and failure model constants and numerical modelling of Charpy impact test of Armour steel. Mater. Sci. Eng. A. 640, 200–209 (2015)

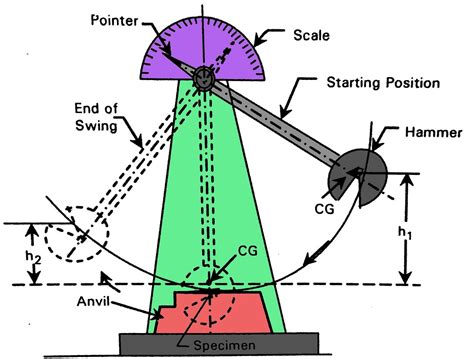

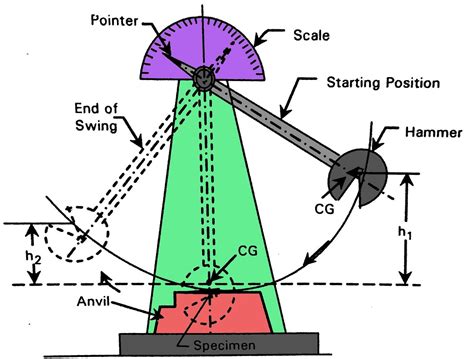

2. 2 Original Charpy Test Development The first pendulum impact machine was designed by S. B. Russell and coworkers in May, 1896. Actual test results using the pendulum machine were reported in 1897 at an .

bourbon that uses green caps on test bottles

charpy impact testing methods

Charpy Impact Test: Briefly discuss using the fracture surface images and the absorbed energy the difference in the impact resistance of the steel sample tested at room temperature and - 59°C. (3 marks) 3. Given the below . FIG. 1—“Textbook” fracture surface showing bright, shiny, faceted region surrounded by ductile fracture area. - "Percent Shear Area Determination in Charpy Impact Testing" Skip to search form Skip to main content Skip to .E23 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials Figure 1. Schematic of Charpy Impact Testing and Izod and Charpy V-notch specimens Figure 2 Charpy V-notch specimen used in this laboratory showing dimensions Figure 3. Schematic of plot of impact energy versus temperature showing sigmoidal curve

Neither ductile nor brittle C. Ductile D. Either ductile or brittle, Charpy Impact test are used to help determine a metals: A. Ductility and Yield Strength B. Hardness and Toughness C. Ductile to Brittle Transition Temp and Toughness D. Notch Sensitivity and Yield Strength, If you were building a guard-rail on a bridge in an area that can .

Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .The Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with peak capacities of 450J and 750J with optional pendulums for 150J, 300J, 450J and 600J.1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energy

The Charpy Impact Test is a standardized test method used to determine the amount of energy absorbed by a material during fracture. This is essential in understanding the material's toughness and its behavior under sudden impact. The test is commonly used in materials science and engineering to evaluate the impact resistance of materials .

We offer Charpy Impact Test equipment and Izod Impact test equipment services. Both methods are popular for determining the toughness or impact strength of a material. Enquiries + 4401522 401375 [email protected] Search. Client Area. Request a quote. Basket. Menu. Close. Calibration & Repair. Calibration & Repair. Calibration & Repair Services >The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

Charpy impact testing was performed on the series of machined specimens with sub-size cross-section to obtain values of CVN impact energy. Fracture toughness test method according to ASTM E1820 .1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energy

charpy impact test sample

A bagagem de mão deve ser obrigatoriamente acomodada nos compartimentos superiores. Por isso, é importante respeitar as dimensões e os pesos permitidos: 35 cm de largura, 55 cm de altura e 25 cm de profundidade, incluindo as rodas. Caso a bagagem esteja fora do padrão estabelecido, o Cliente estará sujeito à cobrança de franquia de bagagem.

charpy impact test shiny area|charpy impact testing procedure